Whether stationary or mobile, and in both vacuum and pressure operation – our rotary blowers ensure excellent performance for a wide range of applications. For example:

- In water management (e.g. for aeration of sedimentation tanks)

- Forced air generation (drying, cooling, separation…)

- Combustion air supply

- For pneumatic conveying of powdered and granular bulk materials

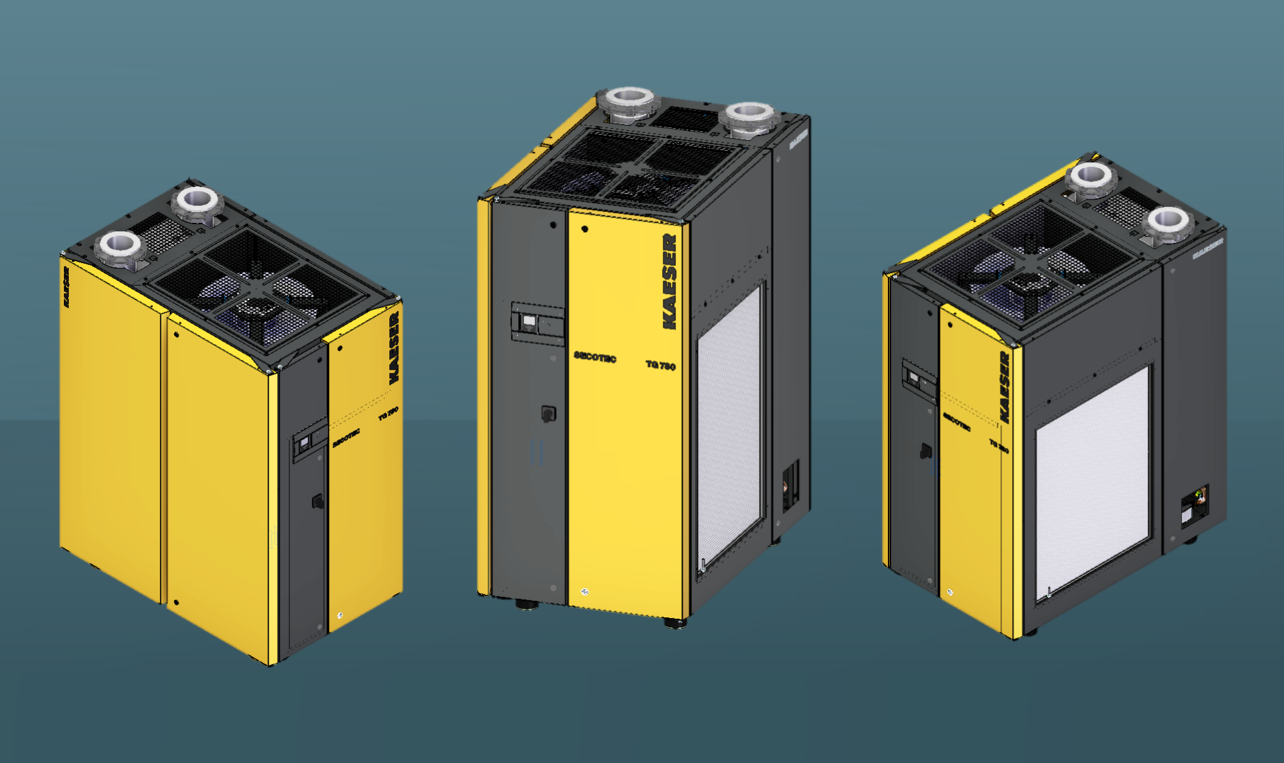

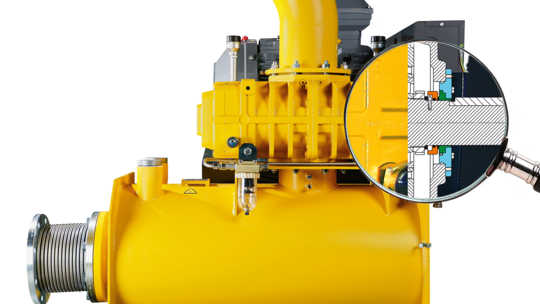

Some bulk materials have to be conveyed in a nitrogen atmosphere within a closed system.

Leakage from system components – including rotary blowers – must therefore be kept to an absolute minimum.

PN series blowers were specially developed for these applications. They are available with three different drive shaft rotary lead-through seals, including a wear-free sliding ring seal.

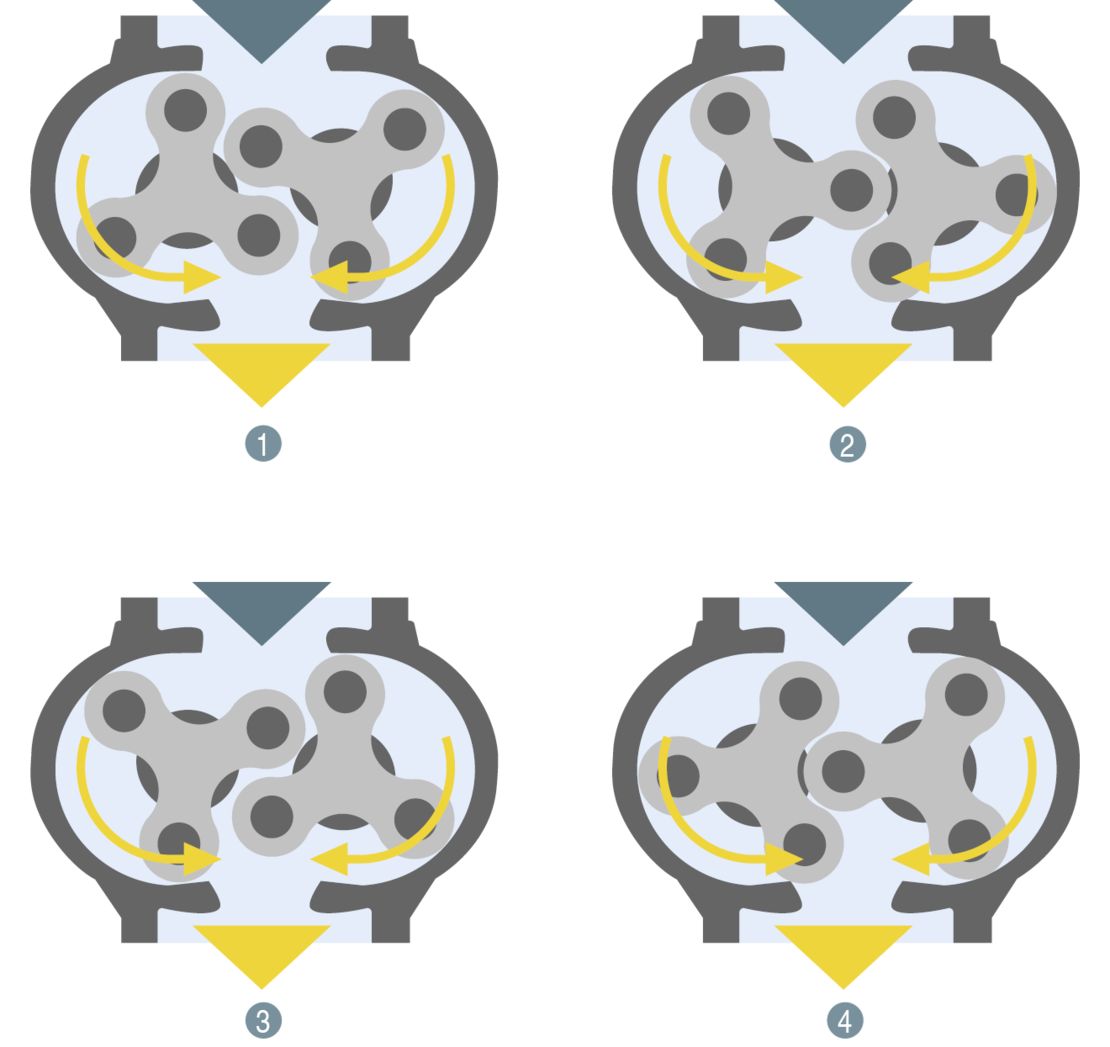

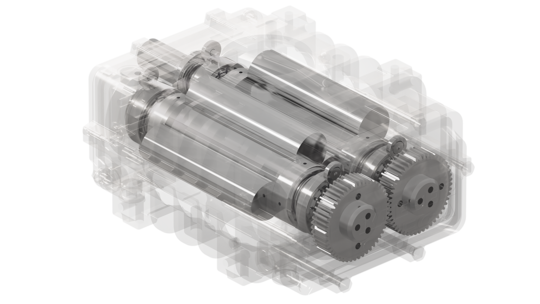

BLOWER BLOCK OMEGA – How it works

- Intake

- Conveying to discharge side

- Pressure equalisation

- Discharge

As the rotors turn, air in the inlet is trapped between the rotor lobes and the casing.

When the advancing lobe reaches the lip of an eccentric bore hole in the casing,

this “pre-inlet channel” allows gradual equalisation of pressure between the trapped inlet air and the air drawn in from the discharge side.

Pressure equalisation in two-lobe blocks occurs abruptly as the advancing lobe crosses the lip of the discharge port.

This is the main reason why three-lobe blocks generate significantly less pulsation than two-lobe blocks.

The air is then finally pushed out against the pressure in the pipe work.