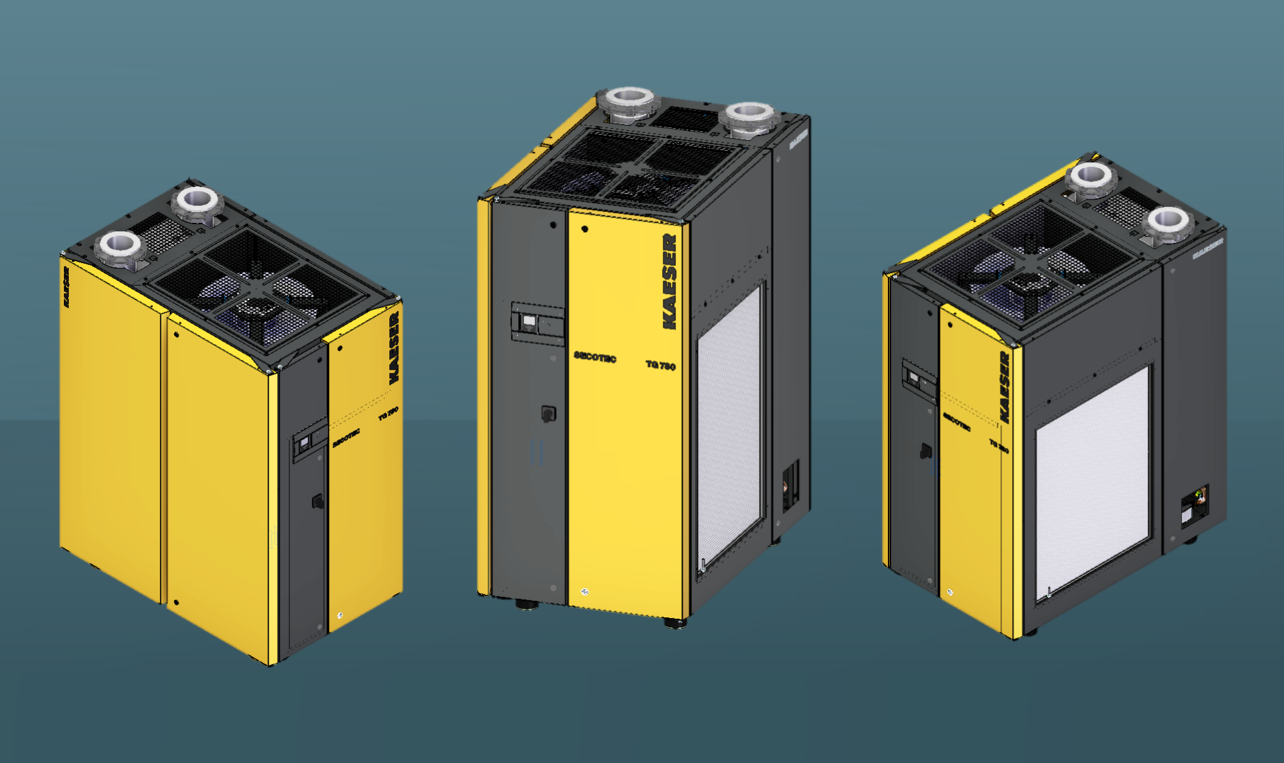

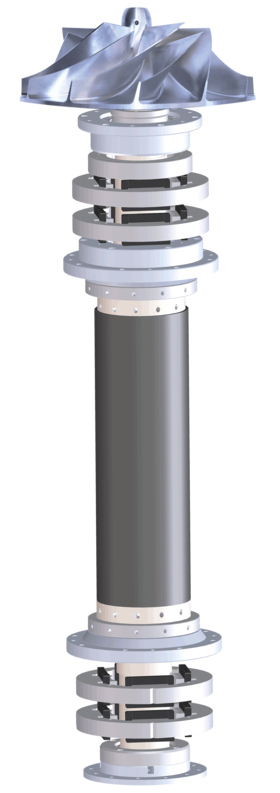

Turbo blowers with wear-free drive motor

The benefits of using magnetic bearings are clear to see:

- Oil-free

- Wear-free

- Maintenance-free

The shaft rotates permanently around its centre of gravity, making it vibration-free. As it remains free from any physical contact, no lubrication is required.

Even frequent start-stop processes are completely wear-free. During shutdown, the shaft is brought to a standstill within the magnetic field. In the unlikely event of a failure of the magnetic bearing controller, the safety bearings will bring the shaft gently to a halt.

The drive motor is airtight, so it cannot be contaminated by the ambient air – substantially increasing the turbo blower’s operational reliability, availability and service life.

Turbo blower technology

Turbo blowers work on the principle of dynamic compression. The impeller of the radially-acting turbo compressor accelerates intake air in the circumferential direction, thereby increasing flow speed and, as a consequence, energy. Part of this

energy is converted into an increase in static pressure in the downstream diffuser. With few moving components in this turbo

machine, an increase in pressure with continuous flow is generated.

The high-speed motor

A high efficiency permanent magnet synchronous motor

(PMSM) is responsible for the direct and loss-free generation of impeller speeds up to 30,000 rpm. The motor’s

impressive performance is made possible due to its

canned motor design, whereby the stator and magnetic

bearing are encapsulated from environmental influences – and without a wearing shaft seal. In order to ensure

effective and controlled cooling, the motor is exclusively

water-cooled, which also protects it from ingress of fine

dust.

The motor shaft is levitated by a magnetic bearing that

not only enables the high motor speeds to be achieved

with zero contact or wear, but also permits virtually unlimited

motor starting frequency.

Furthermore, the active magnetic bearing immediately detects and compensates for deflections to keep the motor

shaft safely in its rotational orbit. The magnetic bearing

control device is protected against power supply failure

by regenerative motor operation. In the event of unexpected, drastic pressure surges, safety bearings

provide further protection for the motor shaft so

that it can be brought to a controlled stop without

damage.